The popularity and production of biogas are rapidly growing. Attitude towards alternative energy sources has changed dramatically because the cost of conventional energy sources is increasing from year to year.

Forecast of the European Biogas Association – biogas and biomethane production can almost double by 2030, and by 2050 the production can grow by more than four times. The potential production of biogas and biomethane in the EU in 2030 can reach 44 billion m3 / year.

“Roadmap for bioenergy development in Ukraine by 2050” provides the establishment and growth of biomethane production in Ukraine to 1700000000 m3/year in 2035 and up to 3 billion m3/year in 2050.

Biogas provides renewable energy and is an effective way to reduce water and air pollution caused by hazardous waste. It also brings profits from energy resources savings.

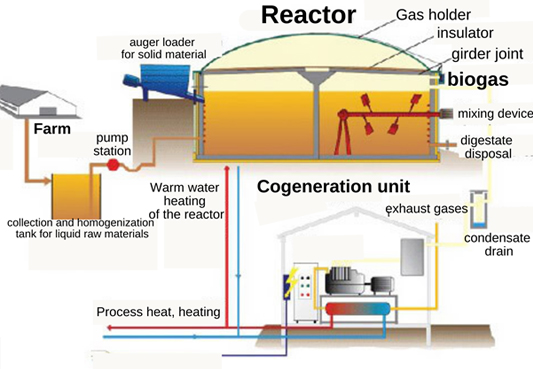

The anaerobic fermentation process is a way to convert biomass (e.g., waste from a yeast plant, dairy plant, or agricultural waste) without air access with the participation of bacteria, where the processed biomass produces mainly methane and processing residues in the form of fertilizers.

Complex organic matter decomposes into CO2 and CH4 during anaerobic fermentation to produce biogas as a mixture of carbon dioxide and methane, where methane can account for up to 70%.

- The process of anaerobic digestion of biomass takes place without oxygen in special digesters tanks. Their design ensures maximum methane emission.

Organic waste suitable for biogas production:

- fruit, berry, vegetable pulp, grape pomace,

- wastewater from dairies – salty and sweet milk whey,

- wastewater and wastes from yeast, starch, and molasses production plants – pulp and syrup.

- potato processing waste: skins, rotten tubers; coffee pulp, runoff from chip plants,

- post-alcohol bard, beer production wastewater, beet pulp,

- manure, poultry manure, slaughterhouse wastes and effluents (blood, fat, intestines),

- fecal sludge from municipal sewage treatment plants,

- sewage from pulp and paper mills and many other industrial enterprises,

- grass, household waste,

- biodiesel production wastes – technical glycerin from the production of biodiesel from rapeseed,

- algae.

For systems with biogas production, we provide:

• For anaerobic sludge treatment – UASB or EGSB type reactors,

• For anaerobic sludge fermentation – contact reactors of ACR or AD types.

Figure 1. Schematic diagram of a biogas plant

Depending on the further conditions of biogas utilization, the construction of biogas systems must include:

- Condensate removal and drying equipment;

- Storage equipment;

- Equipment for sulfur removal;

- Equipment for transportation and pressure control;

- Combustion equipment.