The rapid development of production technology in food and other industries has caused control processes to reduce electricity, gas, and water consumption. These processes led to an increase in pollution concentrations in the production effluents of enterprises. Wastewater contains high concentrations of pollutants, including carbon (BOD, COD), nitrogen (TKN, NH4, NO3, TN), phosphorus (PO4, TP), fats, oils (FOG), suspended solids (TSS), and many other components in various concentrations.

Anaerobic technology should be used for the treatment of highly concentrated industrial effluents.

In the anaerobic treatment of industrial effluent from 85 to 95% of organic compounds present in wastewater decompose to methane and carbon dioxide, the mixture of which is commonly called biogas. The gain of excess biomass in the anaerobic process is negligible, a beneficial financial advantage over aerobic treatment systems. Anaerobic digesters produce biogas, which you can use as additional heat or electricity for production purposes. In this way, you shorten the payback period of your investment and the cost of running the system.

Depending on the composition of your effluent, we use the following types of anaerobic digesters:

- Anaerobic contact reactor (ACR / AD)

- UASB Anaerobic Reactor

- The EGSB high-load anaerobic reactor.

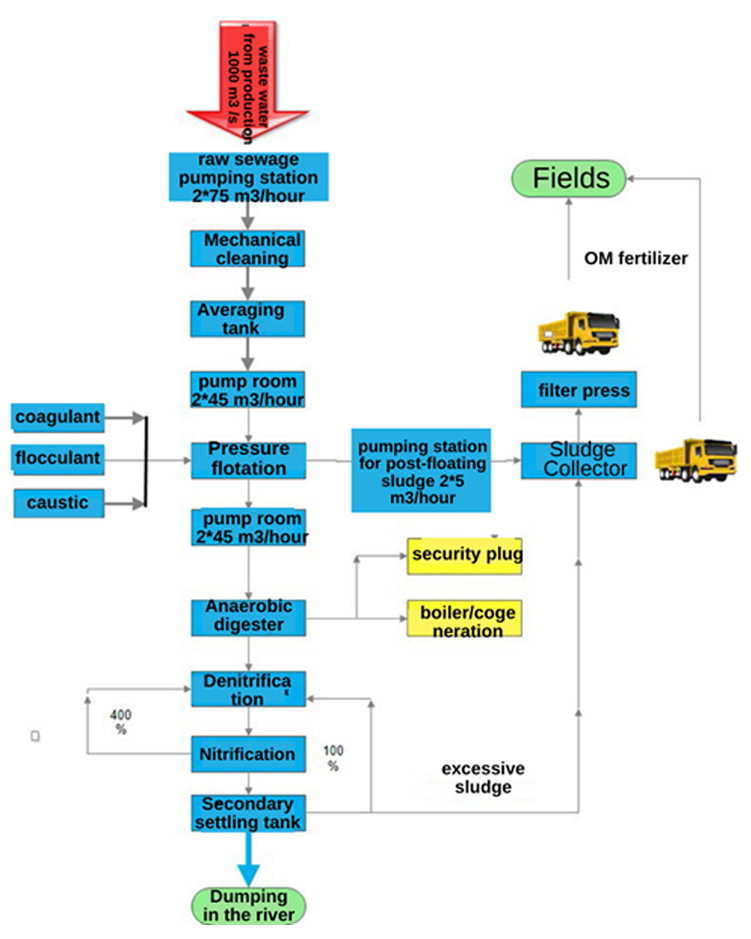

Figure 1. Block diagram of anaerobic treatment plants